Common Rail Diesel Diagnostics in Shropshire & Mid Wales

We provide testing of common rail diesel engine electrics in and around Shrewsbury Shropshire & Welshpool Mid Wales (UK) areas.

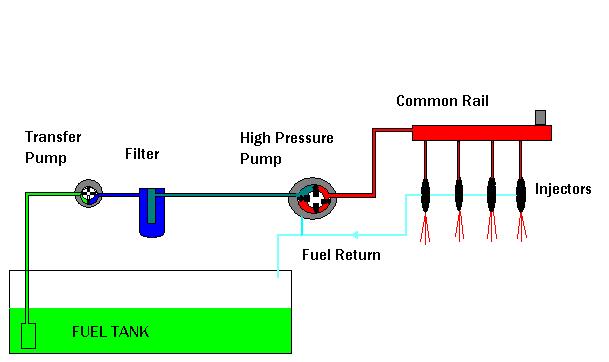

Common rail diesel fuel injection system overview

The common rail diesel injection system was developed by Bosch. Common rail diesel engines can be found in many modern vehicles including cars, vans, buses, trucks,tractors and earthmovers. The common rail diesel fuel system is a programmed electro-mechanical system for control of diesel fluid (fuel) pressure and flow. Diesel fuel injected and atomised in a fine spray to form an air fuel mixture inside the engine combustion chambers must be delivered at the correct moment of the engine cyle to allow efficient burning . There are several manufacturers of common rail diesel fuel injection systems including Bosch , Delphi , Nippondenso , Siemens.

Advantages of the Common Rail Diesel System

The electronically controlled common rail system offers many advantages over traditional systems:

Higher Performance through increased torque at low engine speed

Lower fuel consumption

Lower soot emissions - use of diesel particulate filter ( dpf ) to remove soot particulates via exhaust system.

Reduced Noise

Closed loop feedback control

Programmable characteristics enabling effective use of alternative biofuels

Electronic diagnostics

Diesel Lambda Control using exhaust gas recirculation to reduce NOx emission

Safety Note

Common rail diesel fuel systems operate at very high pressure and can cause severe injury. Fuel pressures of up to 2200bar may be present. Please refer to manufacturers health, safety and training provisions before attempting service or repair of any common rail or pressurised fuel system. We only recommend servicing by qualified personnel.

|

|

| The above diagram shows a very basic layout of a typical common rail diesel fuel system. Electronic sensors and actuators not shown . | Back leak rate comparison test of common rail diesel injectors on Bosch CP1 system fitted to 5 cylinder diesel engine. |

Diesel Control Unit (DCU)

Precision control of fuel injection delivery, quantity and timing allows smooth quiet engine operation with increased performance.

The Diesel control unit (DCU) electronics take inputs from sensors such as throttle pedal position and speed to interpret driver demand, air flow, boost pressure fuel flow, engine mechanical position etc and processes signals in accordance with control unit map parameters to provide outputs to actuators such as pump metering and injectors.

Diesel tuning is possible by Remapping of control unit software or calibration update however care should be taken to avoid insurance and driveability issues.

Engine Control Unit Diagnostics

The common rail diesel fuel injection system is operated and monitored by an electronic control unit (DCU, ECU)

using closed loop fuel control strategy.

If a problem occurs with system operation fault error codes may be logged and stored in engine controller memory.

The control unit is preprogrammed to take appropriate action and may alert the driver by causing the check engine management light

MIL to illuminate and also by reduction of fuel rail pressure to restrict engine performance (limp home mode).

Under certain conditions the engine may be stopped by full shutdown of the injection system with prevention of restart.

Electronic Diagnostics

Logical system diagnostics are first carried out using a scantool with dedicated software to read fault codes

which may be stored on engine management computer.

Scan tool live data(serial data) may be used to monitor fuel rail pressure as seen by engine control ecu.

Vehicles fitted with telematics may transmit engine data back to the service provider.

Advanced diagnostics can be carried out with checks on individual electrical and electronic components by use of oscilloscope testing.

Diesel Fuel System Components

Low pressure fuel pump

Diesel fuel is drawn from the fuel tank by a low pressure transfer pump, this may be an electric pump located in the fuel tank or mechanical pump feeding the main high pressure fuel pump.

Diesel filter

During delivery to the high pressure pump the fuel will pass through at least one fuel filter assembly.

The diesel fuel filters are a service item requiring periodic change.

High Pressure Common Rail Diesel Fuel Pump

Fuel at a constant transfer pressure flows along pipework to the intake of the mechanical high pressure pump which acts to increase fuel pressure to a minimum of approx 220 bar during cranking, to around 1600 bar (approx 23000psi) operating pressure whilst the engine is running at full load. Newer systems are capable of operation at higher fuel pressure.

Pump metering valve

The pressure at the high pressure pump is regulated by proportional electromechanical control of fuel quantity entering the pumping elements within the high pressure pump via inlet metering valve (IMV), or by control of the amount of pressurised fuel returning from the fuel rail to the tank.Lubrication of the pump is provided by fuel circulation.

Diesel Common Rail Injectors

The highly pressurised fuel is pumped to the common rail.

The diesel fuel accumulated in the common rail is delivered to each engine cylinder

by an electronically controlled fuel injector.

Each injector is electronically controlled allowing precise operation to deliver

the required amount of fuel at the correct time.

Common rail diesel fuel systems with electromagnetic solenoid valve type

injectors allow a degree of fuel to return to the tank by internal leakage

through the injector body, referred to as injector back leakage.

Diesel Injector Fault Codes

Injector fault codes may be logged in engine control unit (ecu) memory and read with diagnostic tester.

Fault codes may relate to

Misfire, Open circuit wiring, Short to ground, short to positive etc, and be caused by electronic or mechanical faults.

Injector back leakage test

A small quantity of back leaked fuel provides lubrication for each injector.

Excessive back fuel leakage from fuel injectors may indicate excess wear, and result in lowered common rail fuel pressure. Lower than desired fuel pressure may prevent the vehicle engine from being started.

Seized Injectors

A common problem with removing common rail diesel engines appears to be injectors seized in the cylinder head requiring use of special injector puller kit to remove before injectors can be bench tested.

Fuel Injector Calibration (Coding)

Common fault codes: P2336 , P2337 , P2338

p> The amount of fuel injected is proportional to the injector duration (opening time) , fuel rail pressure , fuel temperature & fluid viscosity.A target value for injector duration under specific conditions is programmed into the diesel control unit (DCU) engine control map.

Fuel injectors are machined to very fine tolerances but because of individual characteristics such as friction, pressure drop, magnetic force , wear during service etc, very slight variations in flow can occur.

Slight difference between target flow and actual flow can occur due to high operating pressures. Certain common rail diesel fuel injectors require calibration during manufacture or overhaul on a specialised diesel injection test rig to produce a data code relating to the characteristics of each individual injector. This data code may be referred to as the C2i code (Delphi) or IMA code (Bosch) depending on manufacturer.

The data code is programmed into the diesel engine control unit

identifying to which cylinder the injector is fitted.

This data code allows the engine control module to correct the pulse duration applied to

each individual injector to maintain optimum performance.

Fitment of replacement injectors will often require new injector codes to the engine control unit.

We have facilities for injector coding of several makes of vehicle.

Commor Rail Fuel Pressure Sensor

A fuel rail pressure sensor is used to provide a fuel pressure feedback signal to the engine controller.

Fuel rail pressure sensor out of range can indicate faults elsewhere in the system

which may cause reduced or excessive fuel pressure

Rail Pressure Relief Valve

A high pressure relief (limiting) valve is often fitted on the common fuel rail to allow fuel flow return to tank if set fuel pressure is exceeded due to wiring or ecu fault.

Useful part numbers:

6C1Q-9H321-AB (finis code 1497165> PRV commonly used on Ford Transit mk7 2.4 and 2.2 TDCi 2006> with Denso fuel system.

166384578R (Renault) - Renault Master - Bosch 0281006188

Servicing

Regular servicing is essential to prevent fuel flow restriction, contamination of precision components and consequent engine running problems.

Fuel filter specification is important to prevent dirt ingress to fuel injection components which will increase wear rate of pump and injectors.

Fuel quality

Fuel quality is of premier importance due to close tolerance of machined precision system components. Misfuelling of a diesel vehicle with another fuel of incorrect grade or viscosity such as petrol can cause extensive damage.

Some common rail pumps have internal coatings intended to prolong component life at high operating pressures which can be destroyed by petrol or solvents.

Certain vehicle insurers are now offering insurance policies protecting against misfuelling.

Common Rail Fuel System Faults Chart

| Typical Fault | Possible effect | Possible Cause |

| High Pressure Fuel System : Loss of Rail pressure |

Difficult staring Non Start Engine cuts out Excessive exhaust emissions Misfire Control unit reverts to limp home mode Rail pressure sensor signal out of expected range

|

Worn fuel injectors with excessive back leak rate. Worn or defective fuel pump Too slow engine cranking speed Fuel pressure regulator,IMV,MPROP, wiring, etc

|

| Low pressure Fuel delivery | Difficult Starting Non start Engine cuts out Pump related fault codes High pressure fuel system faults |

Blocked or damaged fuel supply lines. Fuel filters restricted by blockage Electric fuel pump Low pressure gear pump

|

| Carbon build up around fuel injectors | Loss of cylinder pressure | Loss of seal between fuel injector and cylinder head. may require injectors removed and specialist machining to cylinder head |

| Air intake system faults | Non start Difficult starting Misfire Poor performance under load |

Restricted air filter MAF (Mass Air Flow sensor) fault Loss of Turbocharger boost pressure Exhaust gas recirculation system faults |

| Exhaust system faults | Non start Difficult starting Loss of power |

EGR system restricted , faulty , or inoperative. Blocked or restricted Diesel particulate filter (dpf)

|

| Electrical and electronic faults | Non start Misfire Engine cuts out |

Broken wiring Damaged wiring insulation Corroded connections Low battery voltage Electronic control system faults with Sensors ,Actuators, ECU, coding. Mechanical faults causing electronic system faults. |

Engine cutting out

Faults with the common rail fuel system often result in loss of fuel pressure

causing the engine to cut out .

Fuel Quality resulting in contamination of filters causing flow

restriction.

Incorrect Fuel used causing damage to system components - particularly

when a driver has accidentally refuelled with petrol instead of diesel.

Electrical wiring , Sensor and Actuator faults

Most common rail fuel systems use a fuel accumulator rail mounted pressure sensor which will provide an

electrical feedback signal to the engine management controller.

A loss of fuel pressure or a deviation from the desired amount of fuel pressure may be interpreted as a fuel system leak by the engine management controller in which case total system shut down may occur as a safety feature .

Certain electronic management systems can lock out and prevent engine start

until faults have been repaired.

Faults caused by Exhaust gas recirculation resulting in excessive carbon build up

and blockage of intake components.

Typical example of vehicle suffering from engine running fault

The vehicle in question was a late model luxury car fitted with a high performance

6 cylinder common rail diesel engine which had covered around 90,000 miles.

The customer reported an intermittent fault which caused sluggish acceleration and rough engine running was sometimes present.

Unusually,the dashboard check engine management light , in this particular instance was not illuminated.

The customer had already tried to locate the fault by unplugging and reconnecting wiring to various engine components.

A visual check of the engine bay was done, then using the diagnostic scantool we interrogated the engine control module for stored fault codes.

Several fault codes relating to different fuel injectors, engine stability, and P3505 pre heat device faults were present.

Fault codes were recorded ,then cleared from engine control unit memory.

The vehicle was then road tested to complete a driving cycle by accompanying the customer.

On road test the vehicle hesitated briefly during acceleration.

After road test the control unit memory was once again read using the diagnostic scanner.

A P0204 cylinder fault code relating to an electrical fault within the circuit to cylinder 2 injector valve was present.

Wiggle test: Moving the wiring to cylinder 2 injector located this fault to a bad connection at the injector electrical connector plug , noted audible changes in engine note.

The bad connection was rectified and fault codes once again cleared.

A back leakage test was carried out of all six injectors with the engine running.

Five of the injectors had back leakage values within 10% of each other.

However the remaining 6th fuel injector had almost twice the back leakage fuel flow in comparison

to the others indicating a badly worn fuel injector.

Injectors were removed from the engine for calibration test bench assessment of spray pattern ,recondition and calibration.

The serviced injectors were refitted together with new high pressure pipes

and new fuel filters as recommended and road test carried out resulting in a much smoother drive.